The differences between polyamide and polyester fabrics Exploring the Differences Between Polyamide vs. Polyester Fabrics

The most used synthetic fibers of the textile industry are polyamide and polyester. At first sight, these fibres sound very similar but indeed each have their own unique attributes. Further, the combination of polyamide and polyester leads to a new textile which offers unique features as well.

The textile world met the polyamide (also known as nylon) in the 1930s. Polyamide is widely used for activewear, hosiery, and swimwear because of its resistance to friction (durability) and lightweight properties. It is also used on a widespread scale in the production of auto parts, electronics and even food packaging.

In contrast, Polyester made its debut in the 1950s- it's a man-made synthetic material. Because of its high tensile strength and excellent heat-resistance, these fibers are used widely in manufacturing textiles such as clothing or home furnishings and even industrial products like filter fabrics.

What distinguishes the two fabrics are their chemical compositions. Polyester is made from a polymeric ester, while the chemical structure of polyamide comprises of amides. Due to this difference in chemical composition, the fabrics have different levels of durability and pliability as well ad comfort.

Benefits of Using Polyamide Polyester Blend for Clothing and activewear.

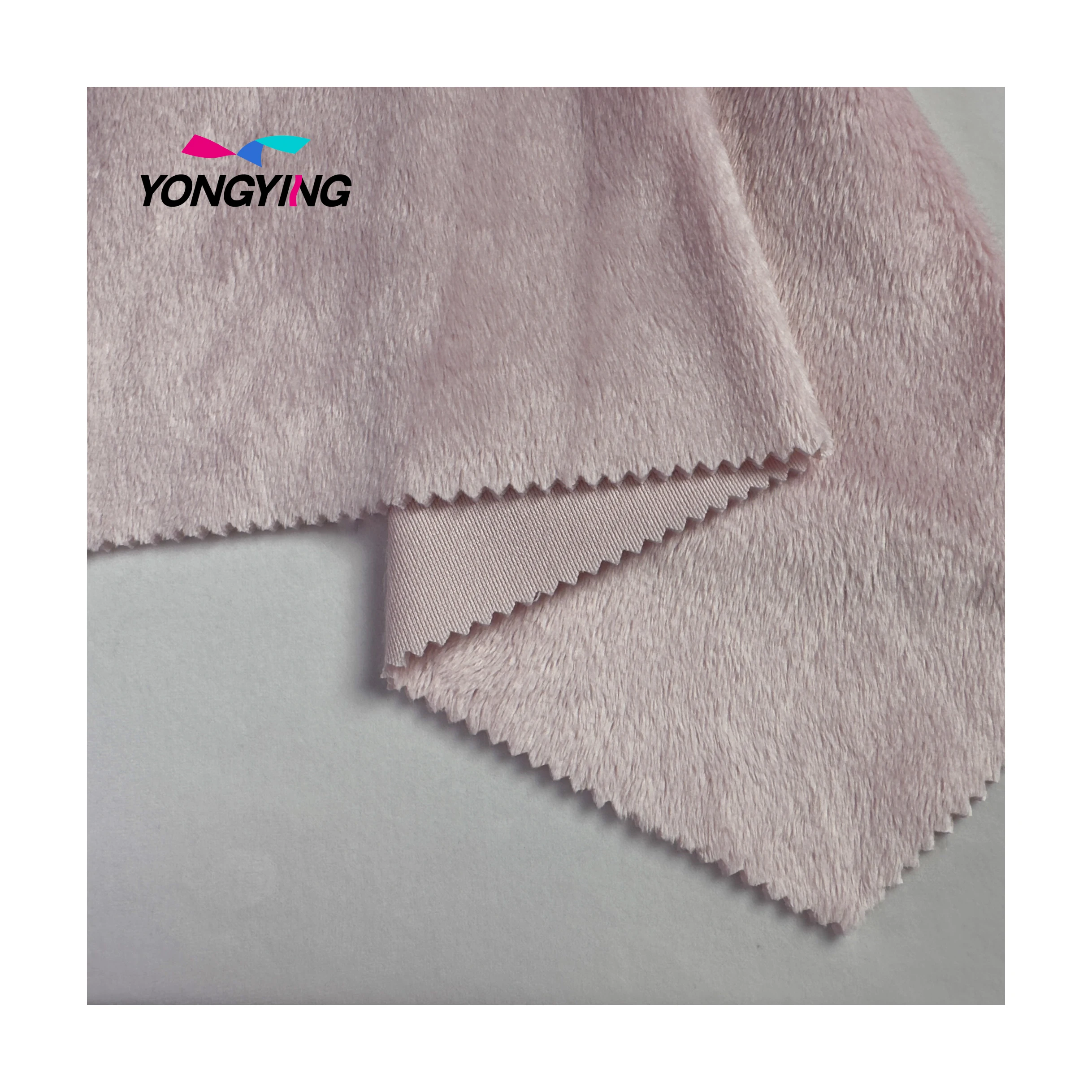

Combining the strength of polyamide and polyester fibers, a textile is created that favors all qualities. T his results in a soft, lightweight and strong fabric well-suited for clothing and exercise gear.

Sportwer and Swimwear:Poliyan: Polyamide polyester blendings that resist moisture What's more, quick-drying traits make it a boon for those who spend time on Great Outdoors with consistency in wet locales. If you are on the go and always working out outside, this material wicks moisture from your skin and dries fast.

In addition to that, polyamide polyester blends are extremely durable and resitant to being worn out through washing of pilling (all the little tangents begin showing). This feature makes them great for base layers or to be used as linings in outer garments.

In addition to being used for garments and activewear, polyamide polyester blends have been favored by the furniture industry. Such blends are particularly useful in providing fabric for those furnishing items that will be required to endure use on a daily basis.

Polyamide polyester blends are resistant to stains, making it a popular choice for some high wear areas and furniture that may be subject to spills such as the arms or legs of chairs & Sofa Legs. In addition, there are a lot of upholstery fabrics that also bring UV protection and then fades will not occur even they have been exposed to sun.

Their sturdiness, ability to resist staining and attractiveness is what most designers consider when designing furniture that combines beauty, functionality & durability so these fabrics are amongst the top choices.

And this is where the sustainability of textiles comes into play, leading to an increased demand for recycled polyamide polyester blends. By itself, the recycled fabrics are produced from post-consumer waste including discarded plastic bottles or fishing nets and pre-consumer waste such as home textile cut-offs(inner cushion fabric), old clothes(100% organic cotton), industrial plastics fruits packaging.

Recycled polyamide polyester blends thus offer an environmentally friendly alternative by limiting waste generation and supporting green textile production. Often these products are checked for compliance with the industry and undergo strict tests to ensure their quality.

Additionally, the use of recycled polyamide polyester textiles is better for the environment. Manufacturing it uses less energy and emits fewer carbon emissions than conventional manufacturing methods. Furthermore, the use of recycled fabrics helps in controlling pollution from oceans and other water bodies.

It is hard to know as things too many trade-offs can be derived when it comes to the sustainability of products, even returning us back what brand you choose where at. Polyester, made from petroleum, which is a nonrenewable organic compound that needs to be extracted, transported and processed as fossil fuel. On the other hand, the production of polyamide emits nitrous oxide in great amounts which is much more powerful greenhouse gas than carbon dioxide.

Although heavy polluting in its production, the sustainability of these two fabrics parts way when they get to their end life. Polyester is recyclable and can be salvaged for further uses like making insulation material, etc. Polyamide, on the other hand, while less easily recyclable than polyester can be bio-degradable as it decomposes to natural substances over time.

In essence, polyamide and polyester fabrics are dedicated synthetic materials with their own set of characteristic features which makes them ideal for different applications in textile production. Combining these fabrics creates a textile which takes the best characteristics of both materials combining them all in one. Considering the holistic advantages and handicaps of sustainability are extremely important when opting for a specific textile to indulge in so that one can have an informed decision.

Changzhou Yongying Textile, as ethical textile producer, holds a Global Recycle Standard certification (GRS) and highlights the significance of eco-friendly development sustainable development. The company is dedicated to utilizing environmentally-friendly methods and materials, which contributes to the protection of Earth's ecosystem. Our commitment to sustainability is fundamental part of our polyamide polyester philosophy, which influences everything from production practices the final design of our products, and is in line with global efforts to encourage eco-friendly business practices.

Changzhou Yongying Textile Co., Ltd. boasts advanced production facility covers over 20,000 square metres, equipped with latest equipment and technologies. company's production staff consists 150 specialists and has a daily production capacity of 75 tons. This polyamide polyestercompany meet large varied orders, and react quickly to changes in market and the demands of the customer. can handle any project that requires quality and prompt delivery.

Changzhou Yongying Textile Co., Ltd. adheres strict processes control quality ensure that every batch fabric is up to international standards. With an innovative quality management system place, business is dedicated to polyamide polyesterflawless high-quality products, earning the trust and satisfaction of global customers. dedication goes beyond compliance in which we continually innovating improve fabric's quality performance, ensuring we are at forefront of technology and satisfaction with customers.

Changzhou Yongying Fabric Co., Ltd.'s products are well-respected worldwide. They're not just popular in market of their own, but they also export their products North America, Europe, North Africa, other regions. This indicates the company's global outlook advantages in the marketplace. strategic market polyamide polyesteris supported by in-depth understanding different cultural preferences and regulatory frameworks, which aids us in tailoring offerings for diverse consumer bases.